Bosch DANESMOOR UTILITY 32-50 Instruction Manual Page 33

- Page / 52

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

C

B

A

RIELLO

RDB OIL PUMP

STARTING THE APPLIANCE

IMPORTANT: Never run the appliance when

the appliance/system is unpressurised

(sealed systems) or empty.

1Check the oil supply is correctly fitted and

in good working order before turning on

the oil supply valves to the boiler.

Turn on the main oil supply valve at the tank

and draw off at least 2

1

/

2

litres of oil until a

steady flow of clear uncontaminated oil can

be seen as follows:

• The oil supply to the boiler should be

primed before the burner is operated to

avoid unnecessary pump wear.

• The use of an oil suction pump will prime

and flush through any oil supply set up

simply and easily, alternatively the

following procedures can be used.

Single pipe gravity feed systems:

Disconnect the flexible oil hose and open

the isolating valve to discharge the oil into a

suitable container.

NOTE: Replace flexible hose at annual

service to prevent possible oil leakage.

If a top entry tank has been used the

pipework will need to be primed before the

oil will discharge under gravity.

When completed, close the isolating valve,

reconnect the flexible oil hose.

Double pipe sub-gravity feed systems

and single pipe suction lift with de-aerator:

To prime a de-aerator, disconnect the

flexible oil inlet hose (G) from the isolation valve

and place in a container of kerosene (H).

Connect a spare flexible oil hose ( I ), to

discharge into container (H). Open the

isolating valve, turn on the power to the boiler

and set the programmer to ON. Prime the

de-aerator until there is a steady flow of oil into

container (H). Turn off the boiler then

reconnect the flexible oil inlet hose (G).

Turn on the boiler, the oil level in the

de-aerator will drop as the oil is used until

the oil is drawn from the tank. If the

de-aerator empties and the burner locks out

before the oil is drawn from the tank, prime

the de-aerator again.

When the oil reaches the pump, bleed

the air from the pump as followes:

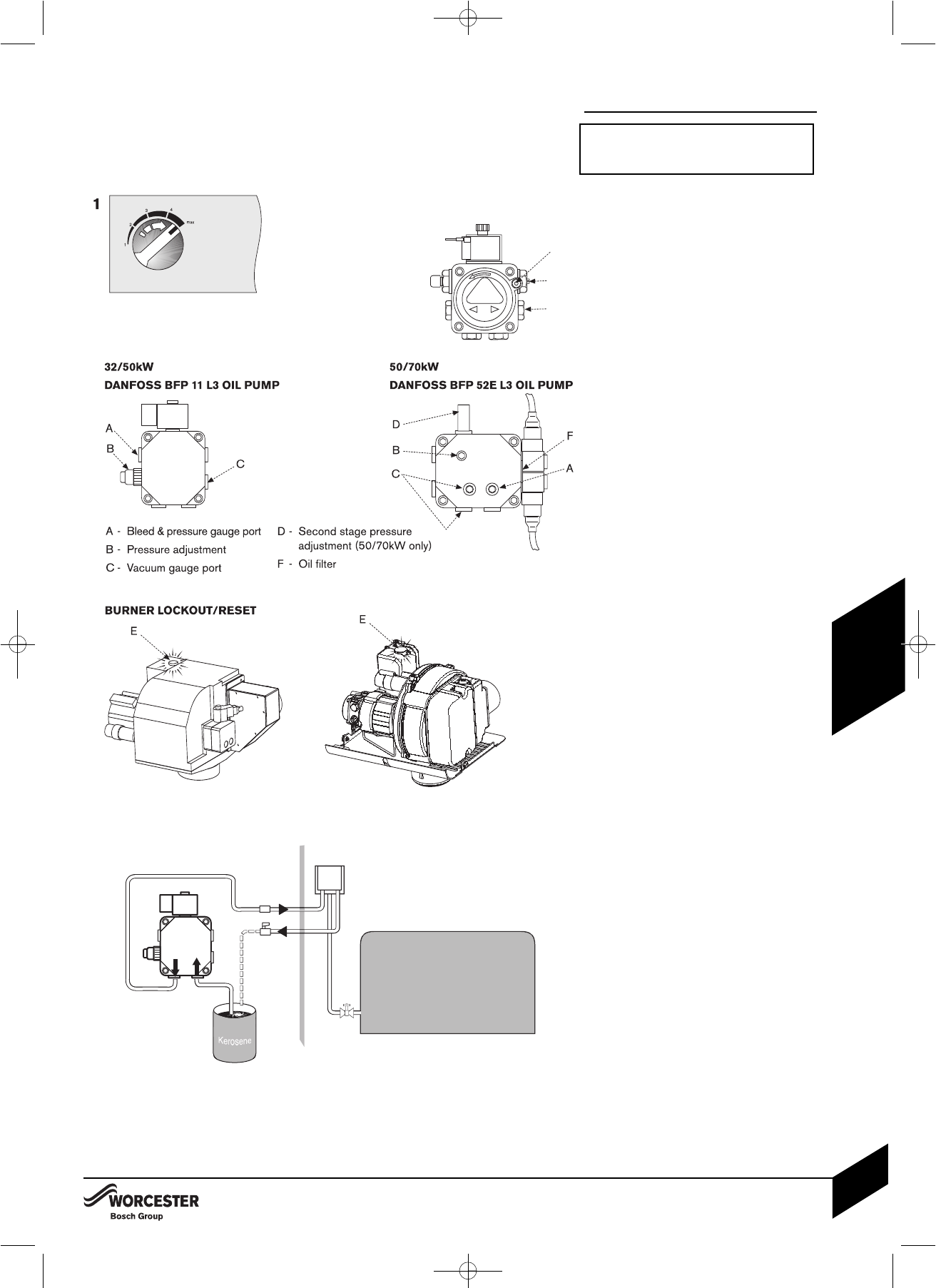

Open the isolating valve and the oil pump

bleed port (A) to discharge into a suitable

container once the boiler is started up.

Switch on the electricity supply to the boiler.

Set the programmer to ON for CH and DHW.

Turn on the boiler control thermostat.

Allow the burner to run through to lockout

indicated by the illumination of the lockout

indicator/reset button (E).

If no oil comes out of the port valve A,

then re-prime the oil line as detailed

above.

Wait 2 minutes then press the lockout reset

button (E).

Repeat the procedure until a steady stream

of oil without air, runs from the bleed port,

then relock bleed port (A).

Switch off the boiler.

Remove the oil pump filter, clean with

kerosene and refit.

The internal filter is accessed by removing

the oil pump cover on the Danfoss BFP 11

L3, Danfoss BFP 52E L3 and Riello RDB.

Safely dispose of the container/discharge.

G

I

H

Return

Flow

TAN K

DANFOSS

PUMP

SHOWN

STARTING THE APPLIANCE

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR UTILITY 32/50 & 50/708 716

109 711B 07.2010

33

COMMISSIONING

8 716 109 711 b 07.10 14/7/10 09:59 Page 33

- GREENSTAR UTILITY 1

- 32/50 & 50/70 1

- INSTALLATION & 2

- SERVICING INSTRUCTIONS 2

- CONTENTS 3

- 8 716 109 711B 07.2010 4

- Check List 5

- TECHNICAL DATA 6

- LAYOUT & COMPONENTS 7

- CLEANING PRIMARY SYSTEMS 8

- MAINS SUPPLY 9

- OIL SUPPLY 10

- WATER SYSTEMS & PIPEWORK 11

- WATER SYSTEMS & PIPEWORK 12

- CONDENSATE & 13

- PRESSURE RELIEF PIPEWORK 13

- BOILER LOCATION & 14

- CLEARANCES 14

- FLUE TERMINAL POSITIONS 16

- CONVENTIONAL FLUE 17

- ROOM SEALED FLUE OPTIONS 18

- UNPACKING THE BOILER 19

- PIPEWORK POSITIONS & 20

- FLUE OPENING 20

- BOILER INSTALLATION 21

- FLUE INSTALLATION 22

- COMBUSTION CHAMBER 23

- PIPEWORK CONNECTIONS 24

- OIL BURNER & PUMP 25

- RIELLO RDB BURNERS 25

- BENTONE STERLING BURNERS 26

- REFITTING COMPONENTS 27

- ELECTRICS 28

- RIELLO CONTROL BOX 29

- PRE-COMMISSIONING CHECKS 31

- APPLIANCE 31

- FILLING THE SYSTEM 32

- STARTING THE APPLIANCE 33

- BENTONE STIRLING BURNERS 35

- WATER TREATMENT 37

- FINISHING COMMISSIONING 38

- INSPECTION AND SERVICE 39

- SHORT PARTS LIST 44

- FAULT FINDING 46

- FAULT FINDING LOGIC FOR 48

- 535 SE/LD RDB CONTROL BOX 48

- SATRONIC CONTROL BOX 49

- SERVICE INTERVAL RECORD 50

(60 pages)

(60 pages) (137 pages)

(137 pages) (16 pages)

(16 pages)

Comments to this Manuals