Bosch DANESMOOR UTILITY 32-50 Instruction Manual Page 24

- Page / 52

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

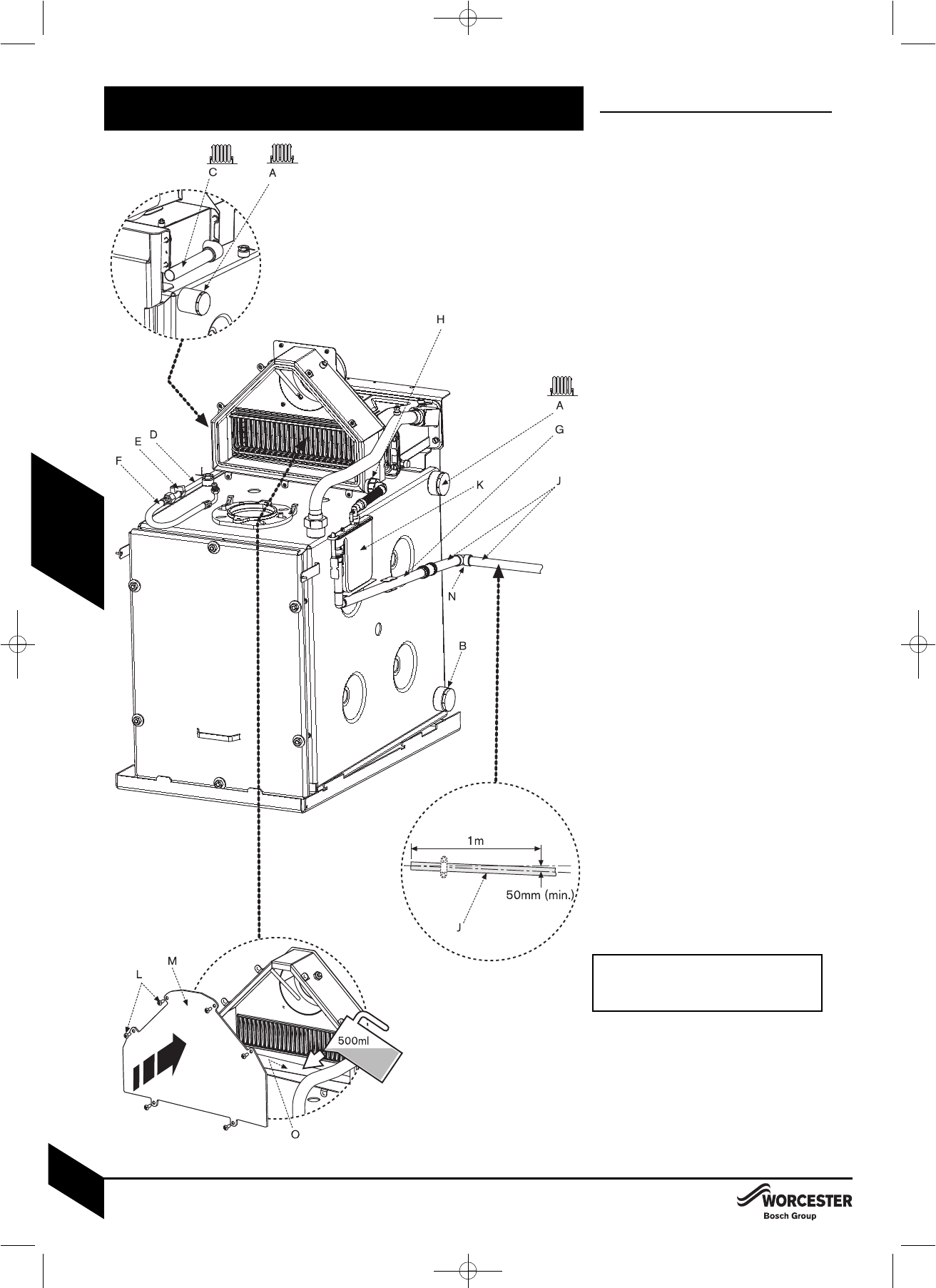

PIPEWORK CONNECTIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR UTILITY 32/50 & 50/708 716

109 711B 07.2010

24

INSTALLATION

CAUTION: ISOLATE THE OIL & WATER MAINS SUPPLY BEFORE STARTING ANY WORK

AND OBSERVE ALL RELEVANT SAFETY PRECAUTIONS.

PIPEWORK CONNECTIONS

A - CH flow /heating vent 1

1

/

2

” Ø

B - Primary drain/cold feed/drain 1

1

/

2

” Ø

C - CH Return 22mmØ copper - male

D - Oil supply pipe - not supplied

E - Oil isolating valve - not supplied

F - Flexible oil hose*

G - Condensate outlet (21.5mmØ) - supplied

H - Flue manifold condensate outlet

J - Condensate pipe - not supplied

K - Internal condensate trap

N - 90° elbows

WATER CONNECTIONS:

Remove the transit bungs from the pipework

connections on the boiler.

NOTE: That surplus water may be present

due to factory testing.

Ensure all pipework is clean.

Align water pipework and connect.

Fit a drain cock to either of the primary cold

feed/drain points (B).

Check that all unused sockets have been

capped.

OIL SUPPLY CONNECTIONS:

Route oil supply pipe (D) along either side of the

boiler as required, finishing close to the burner.

Avoid hot surfaces.

Connect the oil supply pipe (D) to the isolating

valve (E), ensure the valve is closed.

*NOTE: Replace flexible hose at annual

service to prevent possible oil leakage.

Connect the flexible oil hose (F) to the

isolating valve (E).

CONDENSATE CONNECTION:

Connect 21.5mm polypropylene pipe ( J ) (not

supplied) to the condensate waste pipe (G)

flexible push fit connector and terminate to

waste.

Do not use any solvents, adhesives or

lubricants when pushing the pipe into the

rubber connector.

Ensure that the condensate pipe runs away

from the boiler at a constant fall of 50mm

(min.) for every metre.

Seal all condensate pipe joints.

Carefully pour 500ml of water into the

condensate collection ( O ) to fill condensate

trap (K).

Check the water is running away and the

condensate pipework joints are water tight.

Check the flue manifold seal is undamaged

and seated correctly.

Refit flue manifold access cover (M) and

secure with screws (L).

IMPORTANT: The condensate trap must be

correctly filled to prevent the possibility of

potentially harmful flue products escaping

via the condensate pipework.

8 716 109 711 b 07.10 14/7/10 09:59 Page 24

- GREENSTAR UTILITY 1

- 32/50 & 50/70 1

- INSTALLATION & 2

- SERVICING INSTRUCTIONS 2

- CONTENTS 3

- 8 716 109 711B 07.2010 4

- Check List 5

- TECHNICAL DATA 6

- LAYOUT & COMPONENTS 7

- CLEANING PRIMARY SYSTEMS 8

- MAINS SUPPLY 9

- OIL SUPPLY 10

- WATER SYSTEMS & PIPEWORK 11

- WATER SYSTEMS & PIPEWORK 12

- CONDENSATE & 13

- PRESSURE RELIEF PIPEWORK 13

- BOILER LOCATION & 14

- CLEARANCES 14

- FLUE TERMINAL POSITIONS 16

- CONVENTIONAL FLUE 17

- ROOM SEALED FLUE OPTIONS 18

- UNPACKING THE BOILER 19

- PIPEWORK POSITIONS & 20

- FLUE OPENING 20

- BOILER INSTALLATION 21

- FLUE INSTALLATION 22

- COMBUSTION CHAMBER 23

- PIPEWORK CONNECTIONS 24

- OIL BURNER & PUMP 25

- RIELLO RDB BURNERS 25

- BENTONE STERLING BURNERS 26

- REFITTING COMPONENTS 27

- ELECTRICS 28

- RIELLO CONTROL BOX 29

- PRE-COMMISSIONING CHECKS 31

- APPLIANCE 31

- FILLING THE SYSTEM 32

- STARTING THE APPLIANCE 33

- BENTONE STIRLING BURNERS 35

- WATER TREATMENT 37

- FINISHING COMMISSIONING 38

- INSPECTION AND SERVICE 39

- SHORT PARTS LIST 44

- FAULT FINDING 46

- FAULT FINDING LOGIC FOR 48

- 535 SE/LD RDB CONTROL BOX 48

- SATRONIC CONTROL BOX 49

- SERVICE INTERVAL RECORD 50

(60 pages)

(60 pages) (137 pages)

(137 pages) (16 pages)

(16 pages)

Comments to this Manuals